Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E.

(b) Check the fuel sender gauge assembly voltage.

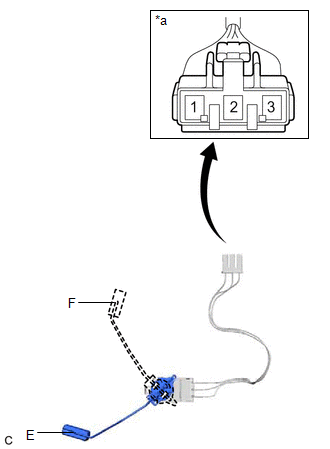

| (1) Apply 5 V between terminals 2 and 3. NOTICE: -

Be careful when connecting the leads, as the fuel sender gauge assembly may be damaged if the leads are connected to the wrong terminals.

-

Do not apply more than 6 V to terminals 2 or 3.

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. | .png) | | *a | Component without harness connected (Fuel Sender Gauge Assembly) | | *b | Voltage Applied between Terminals | | |

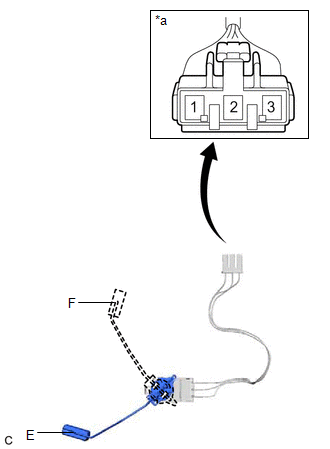

| (2) Measure the voltage according to the value(s) in the table below. Standard Voltage: | Tester Connection | Float Level | Specified Condition | | 1 - 2 | F | 4.255 to 4.605 V* | | Between F and E | 0.345 to 4.605 V* (Gradually changes) | | E | 0.345 to 0.695 V* | *: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the fuel sender gauge assembly. |  | | *a | Component without harness connected (Fuel Sender Gauge Assembly) | | |

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL FUEL SENDER GAUGE ASSEMBLY (a) for Type A: (1) Engage the claw to install the fuel sender gauge assembly to the fuel suction tube with pump and gauge assembly. NOTICE

PRECAUTION CAUTION:

Never perform work on fuel system components near any possible ignition sources.

Vaporized fuel could ignite, resulting in a serious accident.

Do not perform work on fuel s

SEE MORE:

DESCRIPTION The headlight ECU sub-assembly operates using the power source voltage input from the IG terminal and ECUB terminal. The power source voltage of the ECUB terminal is supplied when the main body ECU (multiplex network body ECU) turns the ECUB power supply relay (H-LP LH relay and H-LP RH

DESCRIPTION The radio receiver assembly sends a visual mute signal to the multi-display assembly. As a result, a black screen is displayed when the screen changes so that noise and distorted images are not displayed. When an open exists in the circuit, noise and distorted images will be displayed in

© 2016-2026 Copyright www.lexguide.net

.png)