Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

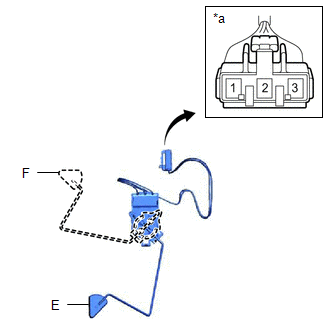

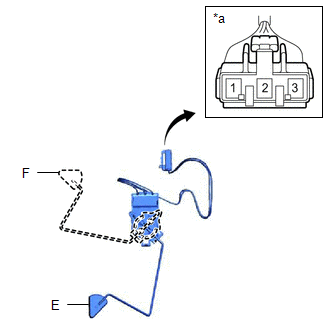

(a) Check that the float moves smoothly between F and E.

(b) Check the fuel sender gauge assembly voltage.

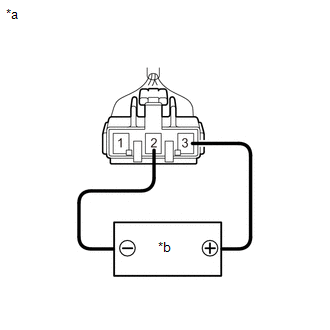

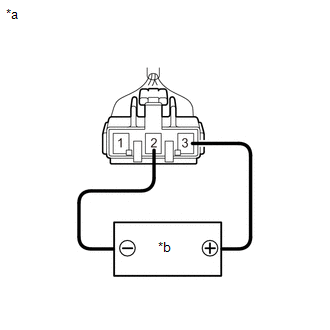

| (1) Apply 5 V between terminals 2 and 3. NOTICE: -

Be careful when connecting the leads, as the fuel sender gauge assembly may be damaged if the leads are connected to the wrong terminals.

-

Do not apply more than 6 V to terminals 2 or 3.

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |  | | *a | Component without harness connected (Fuel Sender Gauge Assembly) | | *b | Voltage Applied between Terminals | | |

| (2) Measure the voltage according to the value(s) in the table below. Standard Voltage: | Tester Connection | Float Level | Specified Condition | | 1 - 2 | F | 4.255 to 4.605 V* | | Between F and E | 0.345 to 4.605 V* (Gradually changes) | | E | 0.345 to 0.695 V* | *: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the fuel sender gauge assembly. |  | | *a | Component without harness connected (Fuel Sender Gauge Assembly) | | |

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL FUEL SENDER GAUGE ASSEMBLY (a) Engage the claw to install the fuel sender gauge assembly to the fuel sub-tank. NOTICE: Be careful not to bend the arm of the fuel send

PRECAUTION CAUTION:

Never perform work on fuel system components near any possible ignition sources.

Vaporized fuel could ignite, resulting in a serious accident.

Do not perform work on fuel s

SEE MORE:

INSTALLATION CAUTION / NOTICE / HINT NOTICE: After installing the luggage door hinge torsion bar, use your hand to open and close the luggage door. Make sure the luggage door can open and close smoothly. PROCEDURE 1. INSTALL LUGGAGE COMPARTMENT DOOR TORSION BAR SUPPORT (a) Install a new luggage comp

REASSEMBLY CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. PRECAUTION NOTICE: After turning the engine switch (for Gasoline Model) or power switch (for HV Model) off, waiting time may be required befor

© 2016-2026 Copyright www.lexguide.net