Lexus ES: Front Left Microphone Circuit Component Internal Failure (B1AA296,B1AA31C)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the No. 1 active noise control microphone system.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| B1AA296 | Front Left Microphone Circuit Component Internal Failure | Stereo component equalizer assembly detects malfunction in No. 1 active noise control microphone for 4 seconds or more continuously when engine speed is 1200 rpm or more* |

|

| B1AA31C | Front Left Microphone Circuit Circuit Voltage Out of Range | Stereo component equalizer assembly detects No. 1 active noise control microphone connection malfunction for 4 seconds or more continuously* |

|

HINT:

*: Malfunction monitoring is not performed under the following conditions, in order to prevent erroneous detection.

- After power switch is turned on (ACC) for 3 seconds or more.

- After the auxiliary battery voltage returns to normal for 3 seconds.

- Before 3 seconds have elapsed after auxiliary battery voltage has returned to normal.

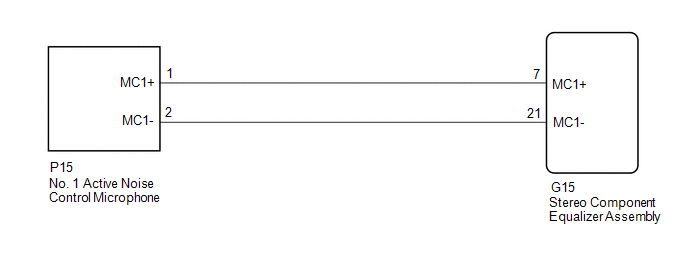

WIRING DIAGRAM

PROCEDURE

| 1. | CLEAR DTC |

(a) Clear the DTCs.

Body Electrical > Active Noise Control > Clear DTCs

|

| 2. | CHECK FOR DTC |

(a) Check for DTCs with all of the detection conditions met.

Body Electrical > Active Noise Control > Trouble CodesOK:

No DTCs are output.

| OK |  | USE SIMULATION METHOD TO CHECK |

|

| 3. | CHECK HARNESS AND CONNECTOR (STEREO COMPONENT EQUALIZER ASSEMBLY - NO. 1 ACTIVE NOISE CONTROL MICROPHONE) |

(a) Disconnect the G15 stereo component equalizer assembly connector.

(b) Disconnect the P15 No. 1 active noise control microphone connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| G15-7 (MC1+) - P15-1 (MC1+) | Always | Below 1 Ω |

| G15-21 (MC1-) - P15-2 (MC1-) | Always | Below 1 Ω |

| G15-7 (MC1+) or P15-1 (MC1+) - Body ground | Always | 10 kΩ or higher |

| G15-21 (MC1-) or P15-2 (MC1-) - Body ground | Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | REPLACE NO. 1 ACTIVE NOISE CONTROL MICROPHONE |

(a) Replace the No. 1 active noise control microphone with a new or known good one.

Click here .gif)

.gif)

|

| 5. | CLEAR DTC |

(a) Clear the DTCs.

Body Electrical > Active Noise Control > Clear DTCs

|

| 6. | CHECK FOR DTC |

(a) Check for DTCs with all of the detection conditions met.

Body Electrical > Active Noise Control > Trouble CodesOK:

No DTCs are output.

| OK |  | END (NO. 1 ACTIVE NOISE CONTROL MICROPHONE IS DEFECTIVE) |

| NG |  | REPLACE STEREO COMPONENT EQUALIZER ASSEMBLY |