Lexus ES: Right Rear Wheel Speed Sensor Supply Voltage Circuit Short to Ground or Open (C14E914)

DESCRIPTION

Refer to DTC C051212

Click here .gif)

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| C14E914 | Right Rear Wheel Speed Sensor Supply Voltage Circuit Short to Ground or Open | An open or short in the speed sensor power supply circuit is detected for 0.12 seconds or more. |

|

| Vehicle Condition | |||

|---|---|---|---|

| Pattern 1 | Pattern 2 | ||

| Diagnosis Condition | - | - | - |

| Malfunction Status | An open in the speed sensor power supply circuit is detected. | ○ | - |

| A short in the speed sensor power supply circuit is detected. | - | ○ | |

| Detection Time | 0.12 seconds or more. | 0.12 seconds or more. | |

| Number of Trips | 1 trip | 1 trip | |

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

WIRING DIAGRAM

Refer to DTC C051212.

Click here .gif)

CAUTION / NOTICE / HINT

NOTICE:

-

After replacing the skid control ECU (brake actuator assembly), perform acceleration sensor zero point calibration and store system information memorization.

Click here

.gif)

-

After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here

.gif)

PROCEDURE

| 1. | CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

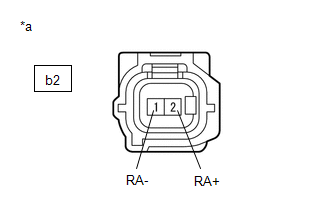

(b) Disconnect the b2 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| b2-2 (RA+) - b2-1 (RA-) | Engine switch on (IG) | 11 to 14 V |

| Result | Proceed to |

|---|---|

| OK | A |

| NG (w/o AVS) | B |

| NG (w/ AVS) | C |

| A |  | REPLACE REAR AXLE HUB AND BEARING ASSEMBLY RH |

| C |  | GO TO STEP 4 |

|

| 2. | CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

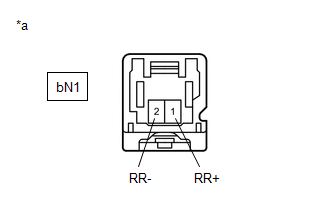

(b) Disconnect the bN1 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| bN1-1 (RR+) - bN1-2 (RR-) | Engine switch on (IG) | 11 to 14 V |

| OK |  | REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

| 3. | CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the bN1 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| bN1-1 (RR+) or A40-22 (RR+) - Body ground | Always | 10 kΩ or higher |

| OK |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 4. | CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

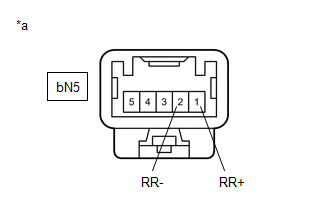

(b) Disconnect the bN5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| bN5-1 (RR+) - bN5-2 (RR-) | Engine switch on (IG) | 11 to 14 V |

| OK |  | REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

| 5. | CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the bN5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| bN5-1 (RR+) or A40-22 (RR+) - Body ground | Always | 10 kΩ or higher |

| OK |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |