Lexus ES: Knock Sensor

Components

COMPONENTS

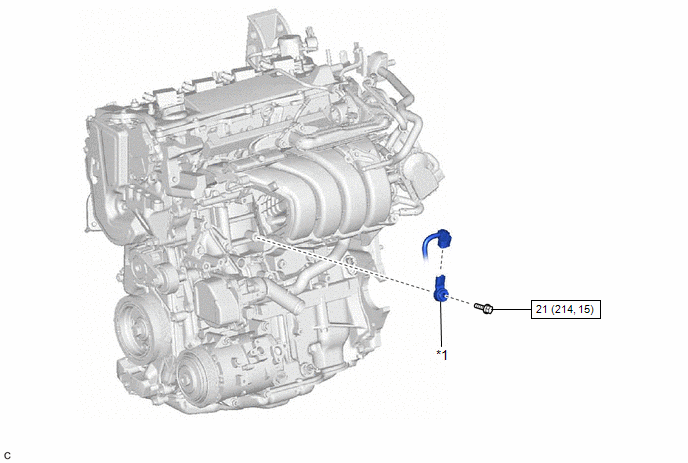

ILLUSTRATION

| *1 | KNOCK CONTROL SENSOR | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

Inspection

INSPECTION

PROCEDURE

1. INSPECT KNOCK CONTROL SENSOR

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the knock control sensor. |

|

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

PROCEDURE

1. INSTALL KNOCK CONTROL SENSOR

HINT:

Perform "Inspection After Repair" after replacing the knock control sensor.

Click here .gif)

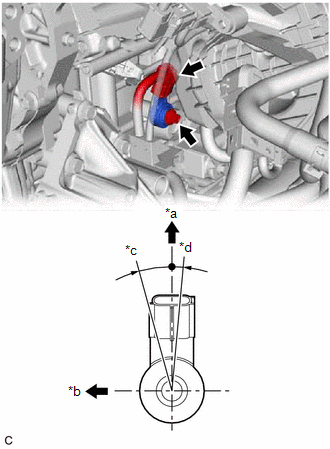

| (a) Install the knock control sensor to the cylinder block sub-assembly with the bolt so that the knock control sensor installation position is as shown in the illustration. Torque: 21 N·m {214 kgf·cm, 15 ft·lbf} NOTICE:

|

|

(b) Connect the knock control sensor connector.

2. INSTALL GENERATOR ASSEMBLY

Click here .gif)

3. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the knock control sensor.

Click here .gif)

.png)