Lexus ES: Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT ENGINE MOUNTING INSULATOR

(a) Install the stay to the front engine mounting insulator with the nut.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

(b) Install the front engine mounting insulator to the front frame assembly with the 3 nuts.

Torque:

72 N·m {734 kgf·cm, 53 ft·lbf}

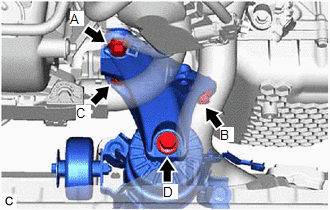

| (c) Install the front engine mounting bracket to the transaxle housing with the 3 bolts. Torque: Bolt (A), (B) and (C) : 42 N·m {428 kgf·cm, 31 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 3 bolts in the order of (B), (C) and (A). |

|

(d) Install the front engine mounting bracket to the front engine mounting insulator with the bolt.

Torque:

Bolt (D) :

72 N·m {734 kgf·cm, 53 ft·lbf}

(e) Install the vacuum hose to the front engine mounting insulator.

(f) Engage the 2 clamps to install the vacuum hoses to the front engine mounting insulator.

(g) Install the No. 1 radiator bracket to the front engine mounting bracket with the bolt.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

(h) Engage the 4 clamps to install the radiator hose, vacuum hoses and No. 2 engine wire to the No. 1 radiator bracket.

2. INSTALL SUSPENSION TOWER DAMPER (w/ Performance Damper)

Click here .gif)

3. INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

.gif)

4. INSTALL NO. 1 ENGINE UNDER COVER

Click here .gif)

.gif)

5. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

.gif)

6. INSTALL FRONT WHEEL OPENING EXTENSION PAD RH

Click here .gif)

.gif)

7. INSTALL VACUUM SWITCHING VALVE (for Active Control Engine Mount System)

Click here .gif)