Lexus ES: Components

COMPONENTS

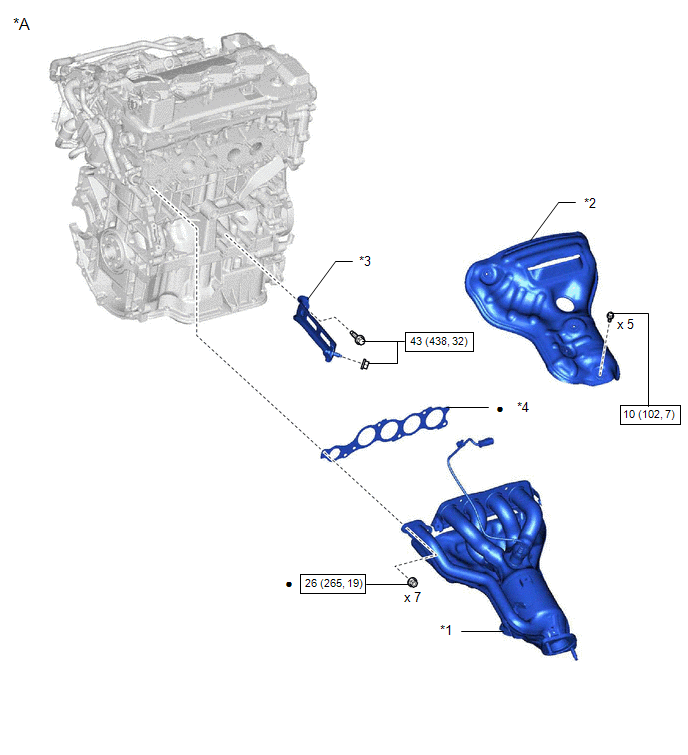

ILLUSTRATION

| *A | Type A | - | - |

| *1 | EXHAUST MANIFOLD (TWC: Front Catalyst) | *2 | NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

| *3 | MANIFOLD STAY | *4 | EXHAUST MANIFOLD TO HEAD GASKET |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

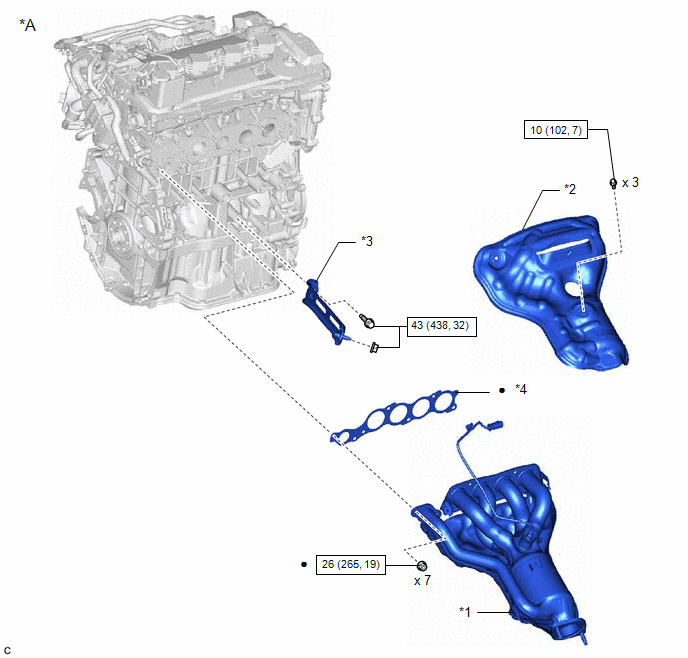

ILLUSTRATION

| *A | Type B | - | - |

| *1 | EXHAUST MANIFOLD (TWC: Front Catalyst) | *2 | NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

| *3 | MANIFOLD STAY | *4 | EXHAUST MANIFOLD TO HEAD GASKET |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

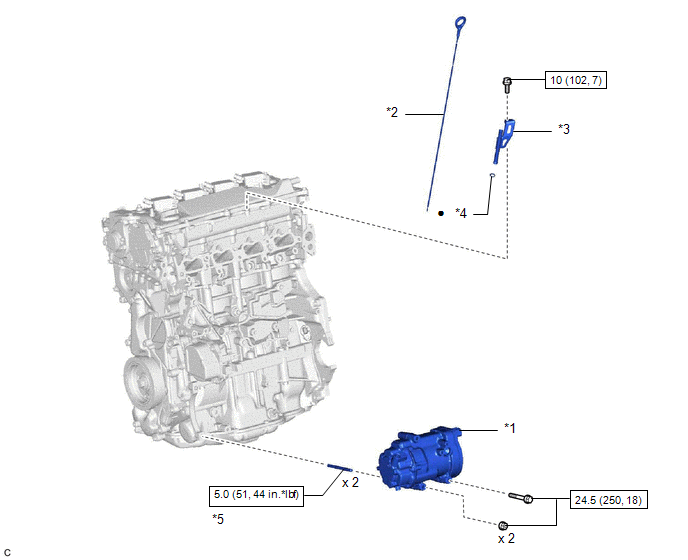

ILLUSTRATION

| *1 | COMPRESSOR WITH MOTOR ASSEMBLY | *2 | ENGINE OIL LEVEL DIPSTICK |

| *3 | ENGINE OIL LEVEL DIPSTICK GUIDE | *4 | O-RING |

| *5 | STUD BOLT | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

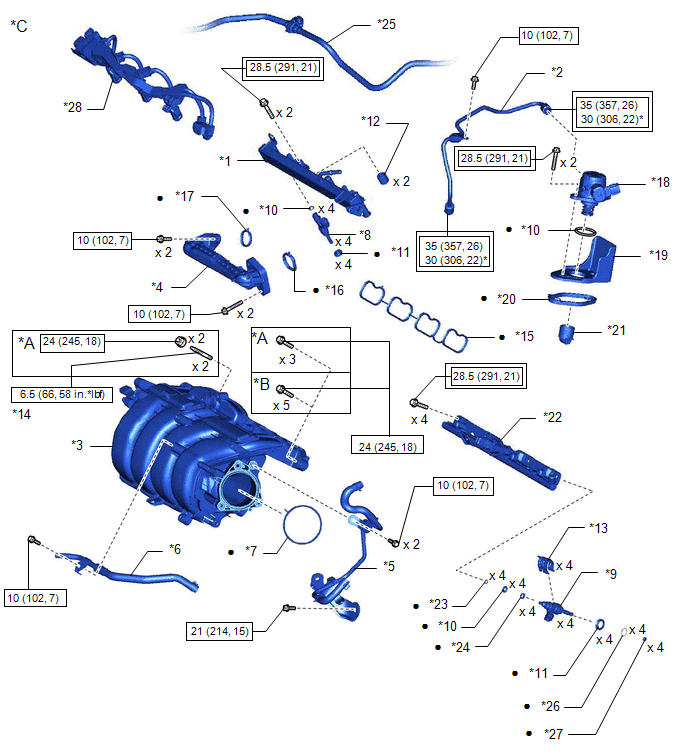

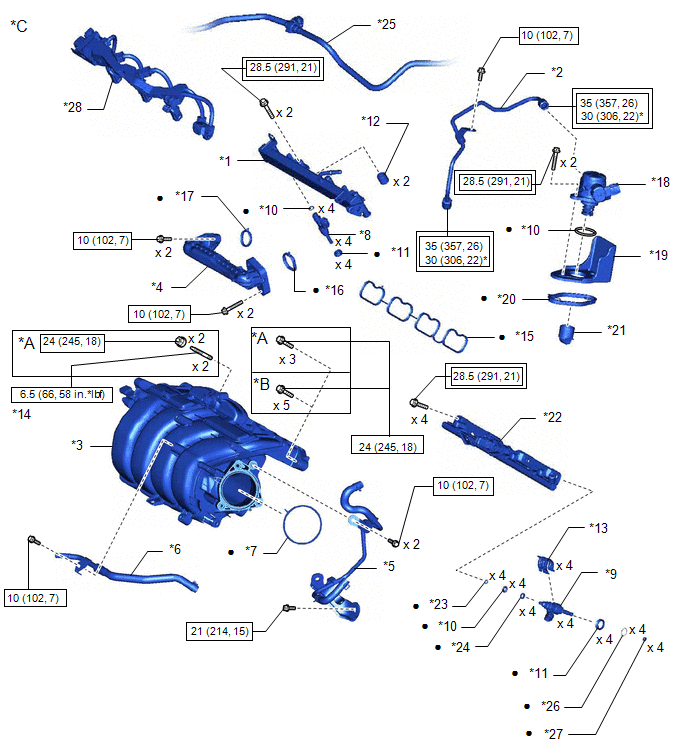

ILLUSTRATION

| *A | w/ Stud Bolt | *B | w/o Stud Bolt |

| *C | for EGR Valve Bracket Connection Type | - | - |

| *1 | FUEL DELIVERY PIPE SUB-ASSEMBLY | *2 | NO. 1 FUEL PIPE SUB-ASSEMBLY |

| *3 | INTAKE MANIFOLD | *4 | NO. 1 EGR PIPE SUB-ASSEMBLY |

| *5 | NO. 2 WATER BY-PASS PIPE | *6 | NO. 3 WATER BY-PASS PIPE |

| *7 | THROTTLE BODY GASKET | *8 | PORT FUEL INJECTOR ASSEMBLY |

| *9 | DIRECT FUEL INJECTOR ASSEMBLY | *10 | O-RING |

| *11 | INJECTOR VIBRATION INSULATOR | *12 | NO. 1 DELIVERY PIPE SPACER |

| *13 | NOZZLE HOLDER CLAMP | *14 | STUD BOLT |

| *15 | NO. 1 INTAKE MANIFOLD TO HEAD GASKET | *16 | EGR VALVE ADAPTER GASKET |

| *17 | EGR INLET GASKET | *18 | FUEL PUMP ASSEMBLY (for High Pressure) |

| *19 | FUEL PUMP FLANGE | *20 | FUEL PUMP SPACER GASKET |

| *21 | FUEL PUMP LIFTER ASSEMBLY | *22 | FUEL DELIVERY PIPE |

| *23 | NO. 3 FUEL INJECTOR BACK-UP RING | *24 | NO. 1 FUEL INJECTOR BACK-UP RING |

| *25 | FUEL TUBE SUB-ASSEMBLY | *26 | C-RING |

| *27 | FUEL INJECTOR SEAL | *28 | NO. 5 ENGINE WIRE |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| * | For use with a union nut wrench | ● | Non-reusable part |

ILLUSTRATION

| *A | w/ Stud Bolt | *B | w/o Stud Bolt |

| *C | for Cylinder Head Cover Sub-assembly Connection Type | - | - |

| *1 | FUEL DELIVERY PIPE SUB-ASSEMBLY | *2 | NO. 1 FUEL PIPE SUB-ASSEMBLY |

| *3 | INTAKE MANIFOLD | *4 | NO. 1 EGR PIPE SUB-ASSEMBLY |

| *5 | NO. 2 WATER BY-PASS PIPE | *6 | NO. 3 WATER BY-PASS PIPE |

| *7 | THROTTLE BODY GASKET | *8 | PORT FUEL INJECTOR ASSEMBLY |

| *9 | DIRECT FUEL INJECTOR ASSEMBLY | *10 | O-RING |

| *11 | INJECTOR VIBRATION INSULATOR | *12 | NO. 1 DELIVERY PIPE SPACER |

| *13 | NOZZLE HOLDER CLAMP | *14 | STUD BOLT |

| *15 | NO. 1 INTAKE MANIFOLD TO HEAD GASKET | *16 | EGR VALVE ADAPTER GASKET |

| *17 | EGR INLET GASKET | *18 | FUEL PUMP ASSEMBLY (for High Pressure) |

| *19 | FUEL PUMP FLANGE | *20 | FUEL PUMP SPACER GASKET |

| *21 | FUEL PUMP LIFTER ASSEMBLY | *22 | FUEL DELIVERY PIPE |

| *23 | NO. 3 FUEL INJECTOR BACK-UP RING | *24 | NO. 1 FUEL INJECTOR BACK-UP RING |

| *25 | FUEL TUBE SUB-ASSEMBLY | *26 | C-RING |

| *27 | FUEL INJECTOR SEAL | *28 | NO. 5 ENGINE WIRE |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| * | For use with a union nut wrench | ● | Non-reusable part |

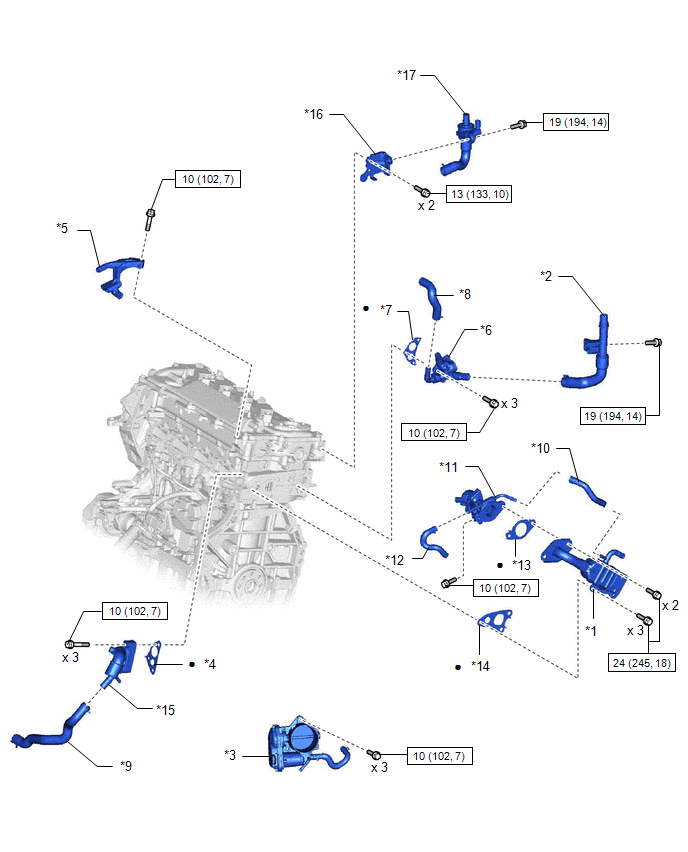

ILLUSTRATION

| *1 | EGR COOLER ASSEMBLY | *2 | NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY |

| *3 | THROTTLE BODY WITH MOTOR ASSEMBLY | *4 | WATER OUTLET GASKET |

| *5 | EGR VALVE BRACKET | *6 | WATER BY-PASS OUTLET SUB-ASSEMBLY |

| *7 | OUTLET WATER PIPE GASKET | *8 | NO. 3 WATER BY-PASS HOSE |

| *9 | NO. 7 WATER BY-PASS HOSE | *10 | NO. 4 WATER BY-PASS HOSE |

| *11 | EGR VALVE ASSEMBLY | *12 | NO. 8 WATER BY-PASS HOSE |

| *13 | EGR VALVE GASKET | *14 | EGR COOLER GASKET |

| *15 | WATER OUTLET | *16 | WATER HOSE CLAMP BRACKET |

| *17 | FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY) | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

ILLUSTRATION

| *1 | IGNITION COIL ASSEMBLY | *2 | ENGINE MOUNTING BRACKET RH |

| *3 | CAM TIMING OIL CONTROL SOLENOID ASSEMBLY | *4 | CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY |

| *5 | CAM TIMING CONTROL MOTOR O-RING | *6 | CRANKSHAFT PULLEY ASSEMBLY |

| *7 | CRANKSHAFT PULLEY BOLT | *8 | O-RING |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

| ★ | Precoated part | - | - |

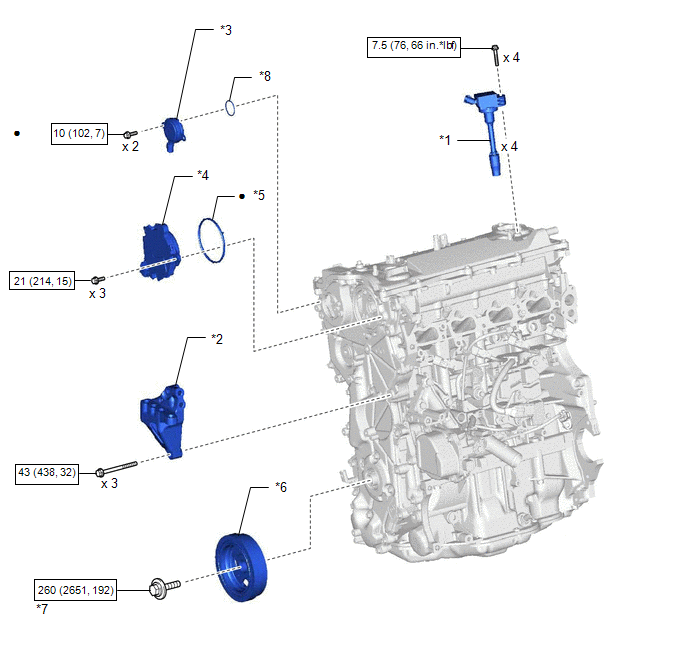

ILLUSTRATION

| *1 | OIL PUMP DRIVE CHAIN SUB-ASSEMBLY | *2 | CAMSHAFT POSITION SENSOR (for Intake Side) |

| *3 | CYLINDER HEAD COVER SUB-ASSEMBLY | *4 | SPARK PLUG TUBE GASKET |

| *5 | NO. 2 TIMING CHAIN COVER ASSEMBLY | *6 | TIMING CHAIN COVER OIL SEAL |

| *7 | CAMSHAFT POSITION SENSOR (for Exhaust Side) | *8 | CYLINDER HEAD COVER GASKET |

| *9 | OIL PUMP DRIVE SPROCKET | *10 | OIL PUMP DRIVE SHAFT SPROCKET |

| *11 | CHAIN TENSIONER PLATE | *12 | CHAIN DAMPER SPRING |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | MP grease | ★ | Precoated part |

.png) | Do not apply lubricants to the threaded parts | - | - |

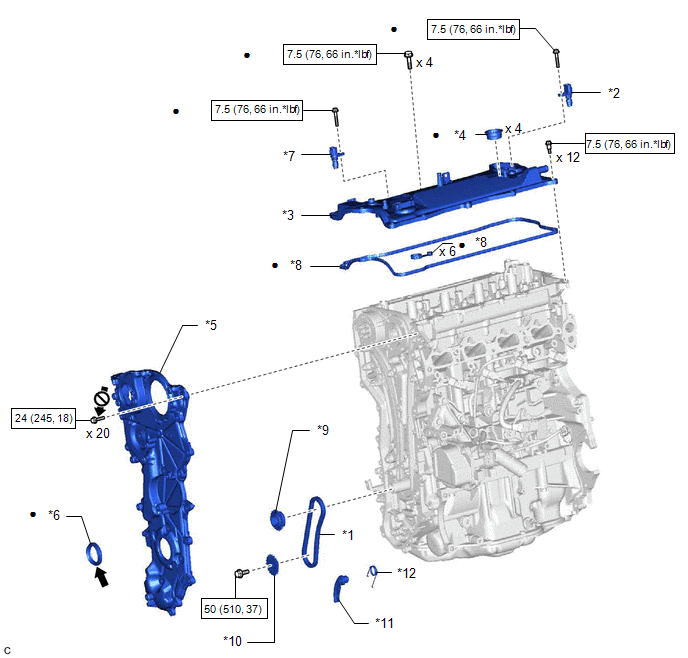

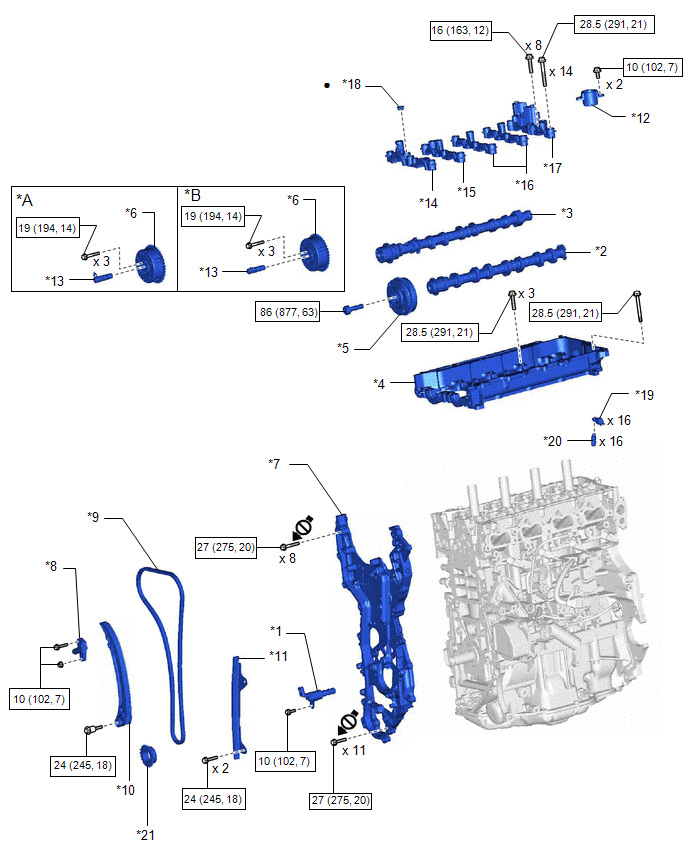

ILLUSTRATION

| *A | Type A | *B | Type B |

| *1 | OIL PRESSURE CONTROL VALVE ASSEMBLY | *2 | CAMSHAFT |

| *3 | NO. 2 CAMSHAFT | *4 | CAMSHAFT HOUSING SUB-ASSEMBLY |

| *5 | CAMSHAFT TIMING GEAR ASSEMBLY | *6 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

| *7 | TIMING CHAIN COVER ASSEMBLY | *8 | NO. 1 CHAIN TENSIONER ASSEMBLY |

| *9 | CHAIN SUB-ASSEMBLY | *10 | CHAIN TENSIONER SLIPPER |

| *11 | NO. 1 CHAIN VIBRATION DAMPER | *12 | FUEL PUMP LIFTER GUIDE |

| *13 | CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY) | *14 | NO. 1 CAMSHAFT BEARING CAP |

| *15 | NO. 2 CAMSHAFT BEARING CAP | *16 | NO. 3 CAMSHAFT BEARING CAP |

| *17 | NO. 4 CAMSHAFT BEARING CAP | *18 | CAMSHAFT BEARING CAP OIL HOLE GASKET |

| *19 | NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY | *20 | VALVE LASH ADJUSTER ASSEMBLY |

| *21 | CRANKSHAFT TIMING SPROCKET | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | Do not apply lubricants to the threaded parts | - | - |

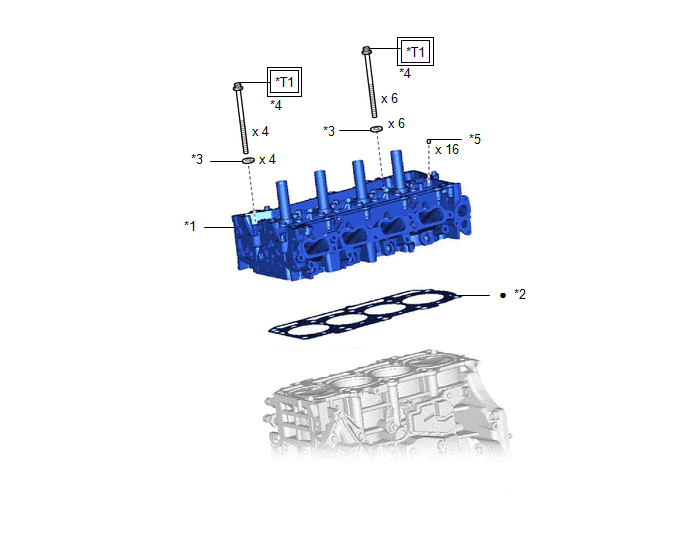

ILLUSTRATION

| *1 | CYLINDER HEAD SUB-ASSEMBLY | *2 | CYLINDER HEAD GASKET |

| *3 | PLATE WASHER | *4 | CYLINDER HEAD SET BOLT |

| *5 | VALVE STEM CAP | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | ● | Non-reusable part |

| *T1 | 1st: 90 (918, 66) 2nd: Turn 90° 3rd: Turn 90° | - | - |