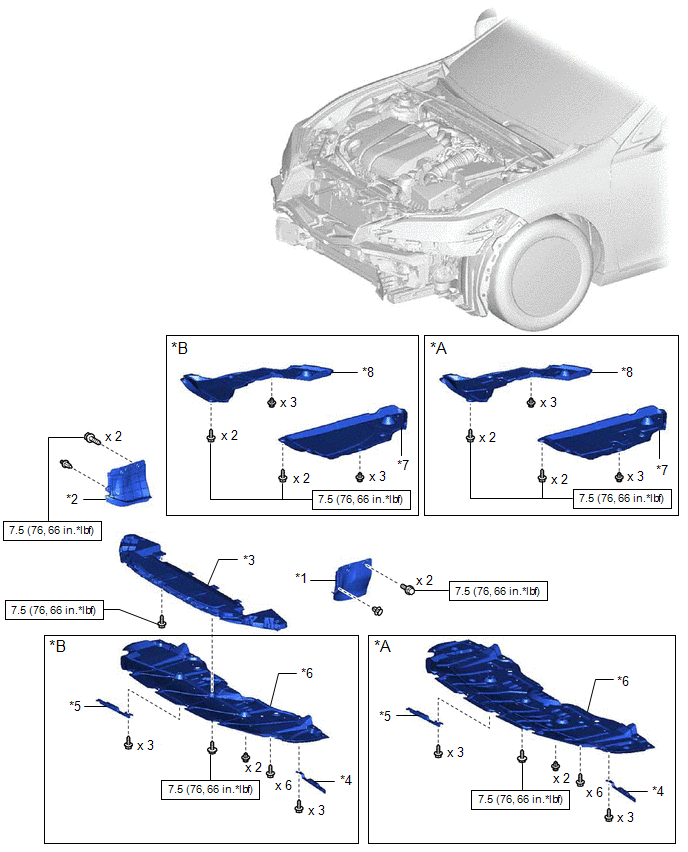

Lexus ES: Components

COMPONENTS

ILLUSTRATION

| *A | Type A | *B | Type B |

| *1 | FRONT FENDER APRON SEAL LH | *2 | FRONT FENDER APRON SEAL RH |

| *3 | FRONT LOWER BUMPER ABSORBER | *4 | FRONT WHEEL OPENING EXTENSION PAD LH |

| *5 | FRONT WHEEL OPENING EXTENSION PAD RH | *6 | NO. 1 ENGINE UNDER COVER |

| *7 | NO. 3 ENGINE UNDER COVER | *8 | NO. 2 ENGINE UNDER COVER |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

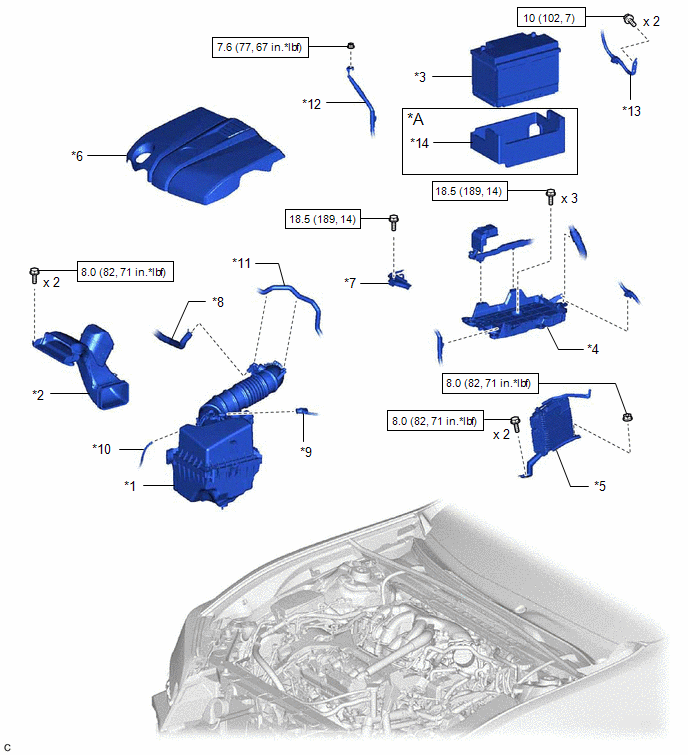

ILLUSTRATION

| *A | w/ Battery Insulator | - | - |

| *1 | AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE | *2 | INLET AIR CLEANER ASSEMBLY |

| *3 | BATTERY | *4 | BATTERY CLAMP SUB-ASSEMBLY |

| *5 | ECM | *6 | V-BANK COVER SUB-ASSEMBLY |

| *7 | NO. 2 BATTERY CLAMP | *8 | NO. 2 VENTILATION HOSE |

| *9 | MASS AIR FLOW METER SUB-ASSEMBLY CONNECTOR | *10 | VACUUM HOSE |

| *11 | NO. 1 FUEL VAPOR FEED HOSE | *12 | ENGINE ROOM MAIN WIRE |

| *13 | EARTH WIRE | *14 | BATTERY INSULATOR |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

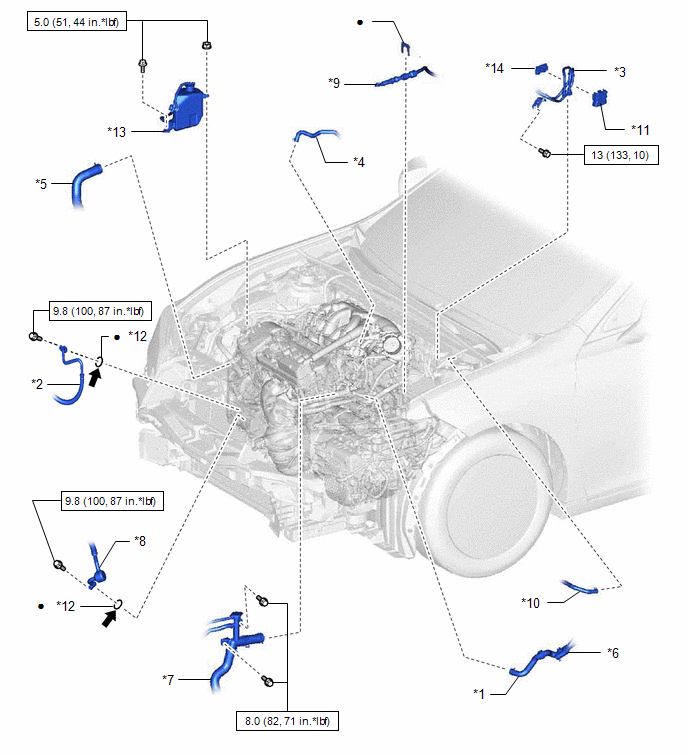

ILLUSTRATION

| *1 | INLET HEATER WATER HOSE | *2 | NO. 1 COOLER REFRIGERANT DISCHARGE HOSE |

| *3 | NO. 1 FUEL HOSE | *4 | NO. 1 FUEL VAPOR FEED HOSE |

| *5 | NO. 2 RADIATOR HOSE | *6 | OUTLET HEATER WATER HOSE |

| *7 | RADIATOR HOSE SUB-ASSEMBLY | *8 | SUCTION HOSE |

| *9 | TRANSMISSION CONTROL CABLE ASSEMBLY | *10 | UNION TO CHECK VALVE HOSE |

| *11 | NO. 1 FUEL PIPE CLAMP | *12 | O-RING |

| *13 | RADIATOR RESERVE TANK ASSEMBLY | *14 | NO. 2 FUEL PIPE CLAMP |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | Compressor oil ND-OIL 12 or equivalent | - | - |

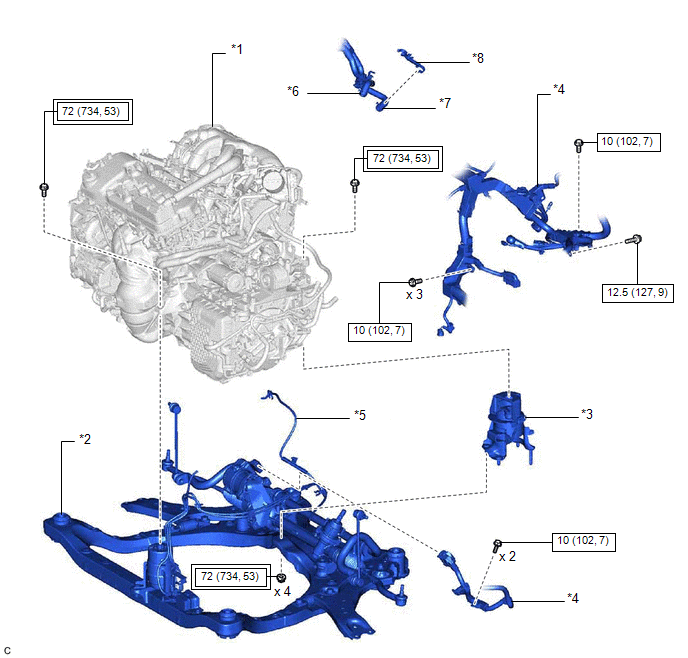

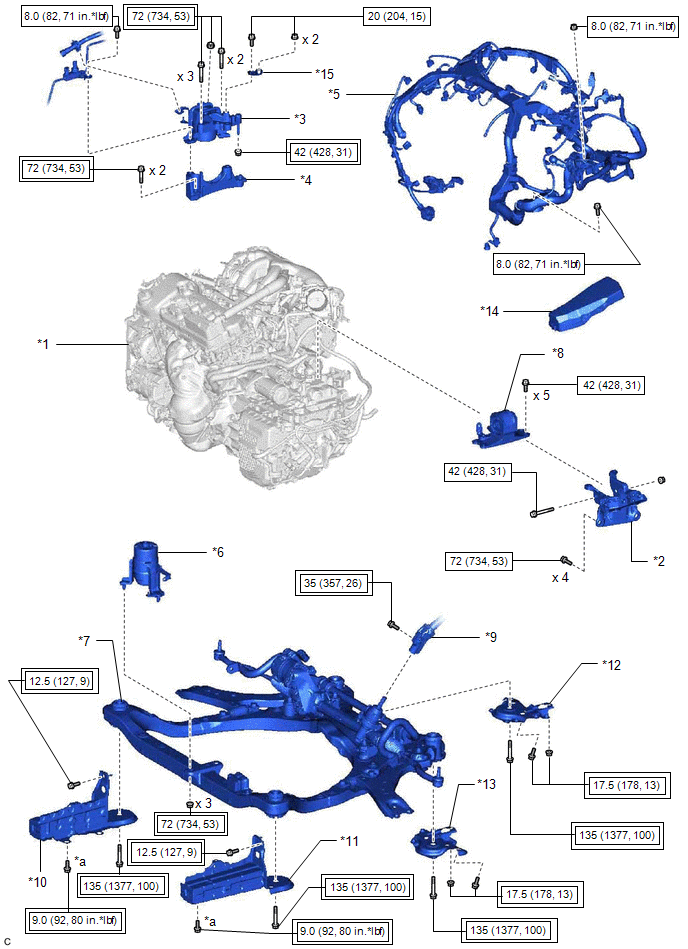

ILLUSTRATION

| *1 | ENGINE ASSEMBLY WITH TRANSAXLE | *2 | FRONT FRAME ASSEMBLY |

| *3 | REAR ENGINE MOUNTING INSULATOR | *4 | WIRE HARNESS |

| *5 | VACUUM HOSE | *6 | NO. 1 WATER BY-PASS HOSE |

| *7 | WATER BY-PASS HOSE ASSEMBLY | *8 | TRANSMISSION BREATHER CLAMP |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

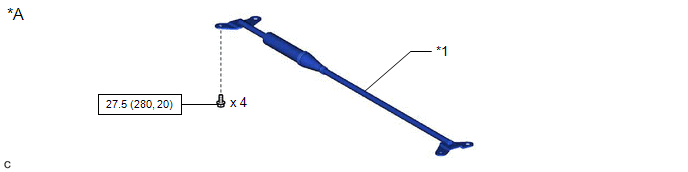

ILLUSTRATION

| *A | w/ Suspension Tower Damper | - | - |

| *1 | SUSPENSION TOWER DAMPER | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

ILLUSTRATION

| *1 | ENGINE ASSEMBLY WITH TRANSAXLE | *2 | ENGINE MOUNTING BRACKET SUB-ASSEMBLY LH |

| *3 | ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH | *4 | ENGINE MOUNTING SPACER |

| *5 | ENGINE WIRE | *6 | FRONT ENGINE MOUNTING INSULATOR |

| *7 | FRONT FRAME ASSEMBLY | *8 | ENGINE MOUNTING INSULATOR LH |

| *9 | STEERING INTERMEDIATE SHAFT ASSEMBLY | *10 | FRONT BUMPER EXTENSION SUB-ASSEMBLY RH |

| *11 | FRONT BUMPER EXTENSION SUB-ASSEMBLY LH | *12 | FRONT SUSPENSION MEMBER BRACKET SUB-ASSEMBLY RH |

| *13 | FRONT SUSPENSION MEMBER BRACKET SUB-ASSEMBLY LH | *14 | NO. 2 RELAY BLOCK COVER |

| *15 | NO. 2 ENGINE MOUNTING STAY RH | - | - |

| *a | w/o Suspension Tower Damper: x 2 w/ Suspension Tower Damper: x 1 | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

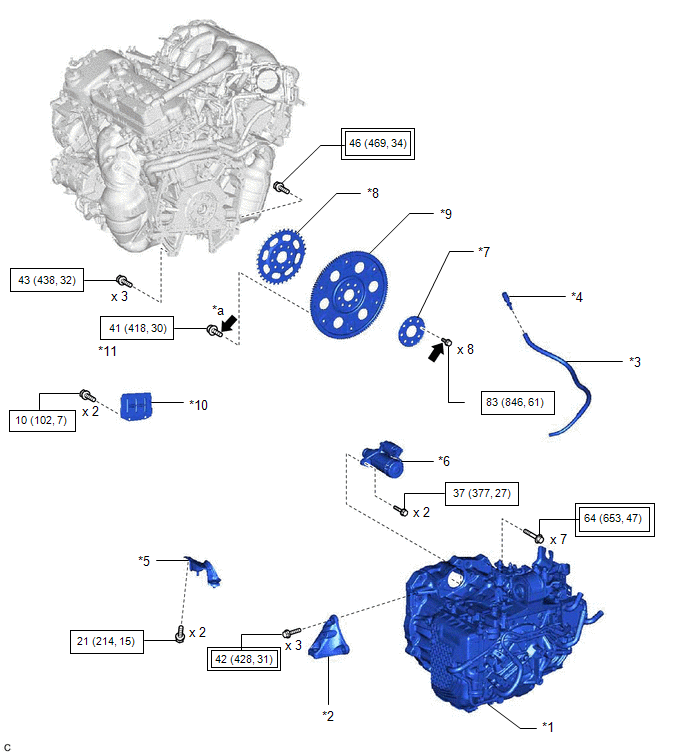

ILLUSTRATION

| *1 | AUTOMATIC TRANSAXLE ASSEMBLY | *2 | FRONT ENGINE MOUNTING BRACKET |

| *3 | BREATHER PLUG HOSE | *4 | BREATHER PLUG SUB-ASSEMBLY |

| *5 | NO. 1 EXHAUST PIPE SUPPORT BRACKET (for Upper Side) | *6 | STARTER ASSEMBLY |

| *7 | REAR DRIVE PLATE SPACER | *8 | NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

| *9 | DRIVE PLATE AND RING GEAR SUB-ASSEMBLY | *10 | FLYWHEEL HOUSING UNDER COVER |

| *11 | DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT | - | - |

| *a | BLACK COLOR: x 1 SILVER COLOR: x 5 | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

.png) | Adhesive 1324 | ★ | Precoated part |