Lexus ES: (Extreme) Hybrid/EV Battery Stack 1 Cell Circuit Voltage Below Threshold (P33EC16,P33ED16)

DESCRIPTION

If the voltage of an HV battery cell is lower than the threshold for a certain amount of time, the battery ECU assembly will interpret this as a malfunction.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Warning Indicate |

|---|---|---|---|---|---|

| P33EC16 | (Extreme) Hybrid/EV Battery Stack 1 Cell Circuit Voltage Below Threshold | The voltage of any cell of the No. 1 HV supply stack sub-assembly has decreased excessively. (1 trip detection logic) |

| Comes on | Master Warning Light: Comes on |

| P33ED16 | (Extreme) Hybrid/EV Battery Stack 2 Cell Circuit Voltage Below Threshold | The voltage of any cell of the No. 2 HV supply stack sub-assembly has decreased excessively. (1 trip detection logic) |

| Comes on | Master Warning Light: Comes on |

CAUTION:

Do not charge the HV battery using the THS charger if DTC P33EC16 or P33ED16 is output.

MONITOR DESCRIPTION

If the battery ECU assembly detects voltage drop in the battery cells, the battery ECU assembly will illuminate the MIL and store a DTC.

MONITOR STRATEGY

| Related DTCs | P33EC (INF P33EC16), P33ED (INF P33ED16): Cell voltage too low |

| Required sensors/components | Battery ECU assembly |

| Frequency of operation | Continuous |

| Duration | TMC's intellectual property |

| MIL operation | Immediately |

| Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

| The monitor will run whenever the following DTCs are not stored | TMC's intellectual property |

| Other conditions belong to TMC's intellectual property | - |

TYPICAL MALFUNCTION THRESHOLDS

| TMC's intellectual property | - |

COMPONENT OPERATING RANGE

| Battery ECU assembly | DTC P33EC (INF P33EC16) is not detected DTC P33ED (INF P33ED16) is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

-

After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

.gif)

-

When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

.gif)

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG) and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for 2 minutes or more.

- Turn the power switch on (IG) and turn the Techstream on.

-

Drive the vehicle on urban roads for approximately 10 minutes.[*1]

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / HV Battery / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to the wiring diagram for DTC P1A001C.

Click here .gif)

CAUTION / NOTICE / HINT

CAUTION:

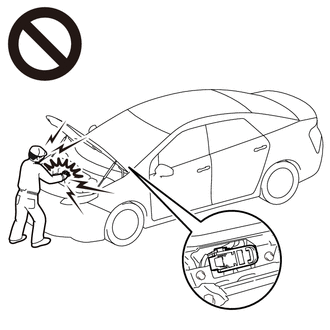

-

Before the following operations are conducted, take precautions to prevent electric shock by turning the power switch off, wearing insulated gloves, and removing the service plug grip from HV battery.

.png)

- Inspecting the high-voltage system

- Disconnecting the low voltage connector of the inverter with converter assembly

- Disconnecting the low voltage connector of the HV battery

-

To prevent electric shock, make sure to remove the service plug grip to cut off the high voltage circuit before servicing the vehicle.

-

After removing the service plug grip from the HV battery, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

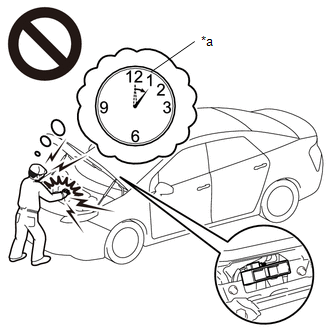

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work.

*a

Without waiting for 10 minutes

Click here

.gif)

.gif)

HINT:

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

-

Make sure to insulate the high-voltage connectors and terminals of the HV battery with insulating tape after removing it.

If the HV battery stored without insulating the connectors and terminals, electric shock or fire may result.

-

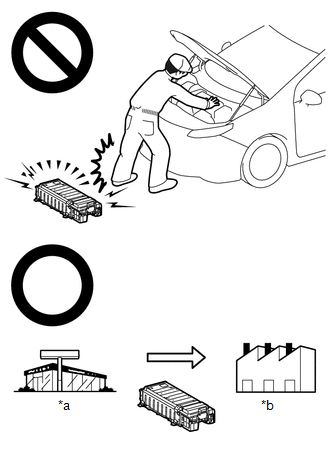

When disposing of an HV battery, make sure to return it through an authorized collection agent who is capable of handling it safely. If the HV battery is returned via the manufacturer specified route, it will be returned properly and in a safe manner by an authorized collection agent.

*a

Dealer

*b

Battery Collection Agent

- Accidents such as electric shock may result if the HV battery is disposed of improperly or abandoned. Therefore, make sure to return all HV batteries through an authorized collection agent.

-

Before returning the HV battery, make sure to perform a recovery inspection.

Click here

.gif)

-

Before returning the HV supply stack sub-assembly, make sure to perform a recovery inspection.

Click here

.gif)

- Make a note of the output DTCs as some of them may be necessary for recovery inspection of the HV battery and HV supply stack sub-assemblies.

-

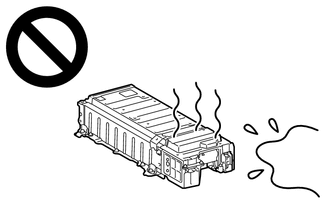

After removing the HV battery, keep it away from water. Exposure to water may cause the HV battery to produce heat, resulting in a fire.

NOTICE:

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

Click here .gif)

.gif)

PROCEDURE

| 1. | CHECK DTC OUTPUT (HV BATTERY, HYBRID CONTROL) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Powertrain / HV Battery and Hybrid Control / Trouble Codes.

(d) Check for DTCs.

Powertrain > HV Battery > Trouble Codes Powertrain > Hybrid Control > Trouble Codes| Result | Proceed to |

|---|---|

| "P33EC16 or P33ED16" only is output, or DTCs except the ones in the table below are also output. | A |

| DTCs of hybrid battery system in the table below are output. | B |

| DTCs of hybrid control system in the table below are output. | C |

| System | Relevant DTC | |

|---|---|---|

| Hybrid battery system | P060A47 | Hybrid/EV Battery Energy Control Module Monitoring Processor Watchdog / Safety MCU Failure |

| P060B49 | Hybrid/EV Battery Energy Control Module A/D Processing Internal Electronic Failure | |

| P060687 | Hybrid/EV Battery Energy Control Module Processor to Monitoring Processor Missing Message | |

| P0E2D00 | Hybrid/EV Battery Energy Control Module Hybrid/EV Battery Monitor Performance | |

| P1AC413 | Hybrid/EV Battery Stack 1 Current Interrupt Device Circuit Open | |

| P1AC49E | Hybrid/EV Battery Stack 1 Current Interrupt Device Stuck On | |

| P1AC513 | Hybrid/EV Battery Stack 2 Current Interrupt Device Circuit Open | |

| P1AC59E | Hybrid/EV Battery Stack 2 Current Interrupt Device Stuck On | |

| Hybrid control system | P0A1F94 | Hybrid/EV Battery Energy Control Module Unexpected Operation |

(e) Turn the power switch off.

| B | .gif) | GO TO DTC CHART (HYBRID BATTERY SYSTEM) |

| C | .gif) | GO TO DTC CHART (HYBRID CONTROL SYSTEM) |

|

| 2. | CHECK DTC |

(a) Check the DTCs that were output when the vehicle was brought to the workshop.

| Result | Proceed to |

|---|---|

| "P33EC16" is also output. | A |

| "P33ED16" is also output. | B |

| B | .gif) | GO TO STEP 8 |

|

| 3. | CHECK CONNECTOR CONNECTION CONDITION (BATTERY ECU ASSEMBLY CONNECTOR) |

CAUTION:

Be sure to wear insulated gloves and protective goggles.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the No. 1 HV battery hose.

Click here .gif)

.gif)

| (c) Check the connector connections and contact pressure of the relevant terminals for the battery ECU assembly. Click here OK: The connector is connected securely and there are no contact problems.

|

| |||||||||||||

(d) Install the No. 1 HV battery hose.

| B | .gif) | CONNECT SECURELY |

| C | .gif) | REPLACE NO. 1 HV SUPPLY STACK SUB-ASSEMBLY |

|

| 4. | CHECK FREEZE FRAME DATA (HV BATTERY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Powertrain / HV battery / Trouble Codes.

(d) Read the value of freeze frame data items "Hybrid/EV Battery Cell 1 Voltage" through "Hybrid/EV Battery Cell 35 Voltage" for DTC P33EC16 and make a note if the value of any is 1.2 V or less.

Powertrain > HV Battery > Trouble Codes(e) Turn the power switch off.

|

| 5. | CHECK NO. 1 HV SUPPLY STACK SUB-ASSEMBLY (HV BATTERY CELL VOLTAGE) |

CAUTION:

- Be sure to wear insulated gloves and protective goggles.

- Disconnect only the connector corresponding to the HV battery cell to be checked. Do not disconnect the other connectors.

NOTICE:

Make sure to use tester probes with a diameter of approximately 0.5 mm (0.0197 in.) when measuring the voltage of each HV battery cell.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the No. 1 HV battery hose.

Click here .gif)

.gif)

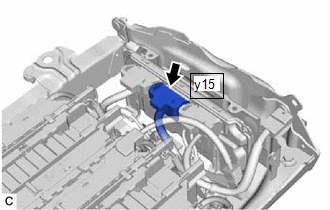

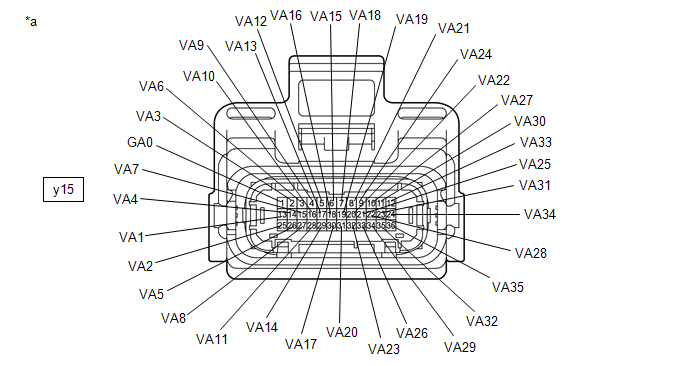

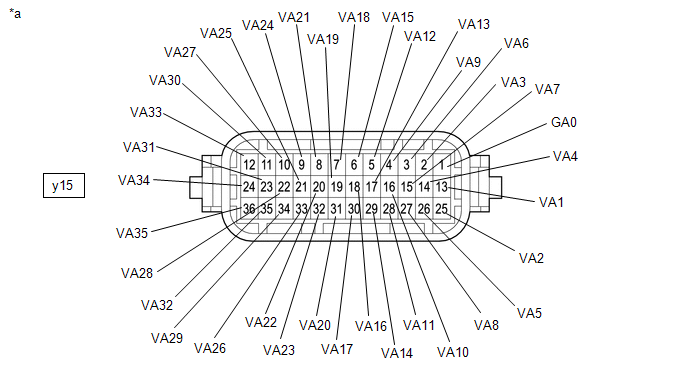

| (c) Disconnect the y15 battery ECU assembly connector. |

|

(d) Measure the voltage according to the value(s) in the table below.

HINT:

Measure the voltage of the HV battery cells whose value in the freeze frame data was 1.2 V or less only.

| *a | Front view of wire harness connector (to Battery ECU Assembly) | - | - |

| HV Battery Cell | Tester Connection | Condition |

|---|---|---|

| 1 | y15-1 (GA0) - y15-13 (VA1) | Always |

| 2 | y15-13 (VA1) - y15-25 (VA2) | Always |

| 3 | y15-25 (VA2) - y15-2 (VA3) | Always |

| 4 | y15-2 (VA3) - y15-14 (VA4) | Always |

| 5 | y15-14 (VA4) - y15-26 (VA5) | Always |

| 6 | y15-26 (VA5) - y15-3 (VA6) | Always |

| 7 | y15-3 (VA6) - y15-15 (VA7) | Always |

| 8 | y15-15 (VA7) - y15-27 (VA8) | Always |

| 9 | y15-27 (VA8) - y15-4 (VA9) | Always |

| 10 | y15-4 (VA9) - y15-16 (VA10) | Always |

| 11 | y15-16 (VA10) - y15-28 (VA11) | Always |

| 12 | y15-28 (VA11) - y15-5 (VA12) | Always |

| 13 | y15-5 (VA12) - y15-17 (VA13) | Always |

| 14 | y15-17 (VA13) - y15-29 (VA14) | Always |

| 15 | y15-29 (VA14) - y15-6 (VA15) | Always |

| 16 | y15-6 (VA15) - y15-18 (VA16) | Always |

| 17 | y15-18 (VA16) - y15-30(VA17) | Always |

| 18 | y15-30(VA17) - y15-7 (VA18) | Always |

| 19 | y15-7 (VA18) - y15-19 (VA19) | Always |

| 20 | y15-19 (VA19) - y15-31 (VA20) | Always |

| 21 | y15-31 (VA20) - y15-8 (VA21) | Always |

| 22 | y15-8 (VA21) - y15-20(VA22) | Always |

| 23 | y15-20(VA22) - y15-32 (VA23) | Always |

| 24 | y15-32 (VA23) - y15-9 (VA24) | Always |

| 25 | y15-9 (VA24) - y15-21 (VA25) | Always |

| 26 | y15-21 (VA25) - y15-33 (VA26) | Always |

| 27 | y15-33 (VA26) - y15-10(VA27) | Always |

| 28 | y15-10(VA27) - y15-22 (VA28) | Always |

| 29 | y15-22 (VA28) - y15-34 (VA29) | Always |

| 30 | y15-34 (VA29) - y15-11 (VA30) | Always |

| 31 | y15-11 (VA30) - y15-23 (VA31) | Always |

| 32 | y15-23 (VA31) - y15-35 (VA32) | Always |

| 33 | y15-35 (VA32) - y15-12 (VA33) | Always |

| 34 | y15-12 (VA33) - y15-24 (VA34) | Always |

| 35 | y15-24 (VA34) - y15-36 (VA35) | Always |

CAUTION:

Make sure not to cross the electrodes of an electrical tester measurement terminals.

NOTICE:

Make sure to check the polarity of each terminal (positive (+) or negative (-)) before connecting a tester.

| Result | Proceed to |

|---|---|

| The voltage between the terminals is 1.2 V or less. | A |

| Other than above | B |

(e) Reconnect the y15 battery ECU assembly connector.

(f) Install the No. 1 HV battery hose.

| B | .gif) | REPLACE BATTERY ECU ASSEMBLY |

|

| 6. | CHECK BATTERY ECU ASSEMBLY (GA0 - VA35) |

NOTICE:

Make sure to use tester probes with a diameter of approximately 0.5 mm (0.0197 in.) when measuring the resistance.

(a) Remove the battery ECU assembly.

Click here .gif)

.gif)

(b) Measure the resistance according to the value(s) in the table below.

HINT:

Only inspect the terminals of the battery ECU assembly which correspond to the HV battery cells which measured 1.2 V or less in the previous step.

| *a | Component without harness connected (Battery ECU Assembly) | - | - |

Standard Resistance:

| HV Battery Cell | Tester Connection (Tester Probe Polarity) | Condition | Specified Condition |

|---|---|---|---|

| 1 | y15-1 (GA0) (-) - y15-13 (VA1) (+) | Always | 50 kΩ or more |

| 2 | y15-13 (VA1) (-) - y15-25 (VA2) (+) | Always | 50 kΩ or more |

| 3 | y15-25 (VA2) (-) - y15-2 (VA3) (+) | Always | 50 kΩ or more |

| 4 | y15-2 (VA3) (-) - y15-14 (VA4) (+) | Always | 50 kΩ or more |

| 5 | y15-14 (VA4) (-) - y15-26 (VA5) (+) | Always | 50 kΩ or more |

| 6 | y15-26 (VA5) (-) - y15-3 (VA6) (+) | Always | 50 kΩ or more |

| 7 | y15-3 (VA6) (-) - y15-15 (VA7) (+) | Always | 50 kΩ or more |

| 8 | y15-15 (VA7) (-) - y15-27 (VA8) (+) | Always | 50 kΩ or more |

| 9 | y15-27 (VA8) (-) - y15-4 (VA9) (+) | Always | 50 kΩ or more |

| 10 | y15-4 (VA9) (-) - y15-16 (VA10) (+) | Always | 50 kΩ or more |

| 11 | y15-16 (VA10) (-) - y15-28 (VA11) (+) | Always | 50 kΩ or more |

| 12 | y15-28 (VA11) (-) - y15-5 (VA12) (+) | Always | 50 kΩ or more |

| 13 | y15-5 (VA12) (-) - y15-17 (VA13) (+) | Always | 50 kΩ or more |

| 14 | y15-17 (VA13) (-) - y15-29 (VA14) (+) | Always | 50 kΩ or more |

| 15 | y15-29 (VA14) (-) - y15-6 (VA15) (+) | Always | 50 kΩ or more |

| 16 | y15-6 (VA15) (-) - y15-18 (VA16) (+) | Always | 50 kΩ or more |

| 17 | y15-18 (VA16) (-) - y15-30 (VA17) (+) | Always | 50 kΩ or more |

| 18 | y15-30 (VA17) (-) - y15-7 (VA18) (+) | Always | 50 kΩ or more |

| 19 | y15-7 (VA18) (-) - y15-19 (VA19) (+) | Always | 50 kΩ or more |

| 20 | y15-19 (VA19) (-) - y15-31 (VA20) (+) | Always | 50 kΩ or more |

| 21 | y15-31 (VA20) (-) - y15-8 (VA21) (+) | Always | 50 kΩ or more |

| 22 | y15-8 (VA21) (-) - y15-20 (VA22) (+) | Always | 50 kΩ or more |

| 23 | y15-20 (VA22) (-) - y15-32 (VA23) (+) | Always | 50 kΩ or more |

| 24 | y15-32 (VA23) (-) - y15-9 (VA24) (+) | Always | 50 kΩ or more |

| 25 | y15-9 (VA24) (-) - y15-21 (VA25) (+) | Always | 50 kΩ or more |

| 26 | y15-21 (VA25) (-) - y15-33 (VA26) (+) | Always | 50 kΩ or more |

| 27 | y15-33 (VA26) (-) - y15-10 (VA27) (+) | Always | 50 kΩ or more |

| 28 | y15-10 (VA27) (-) - y15-22 (VA28) (+) | Always | 50 kΩ or more |

| 29 | y15-22 (VA28) (-) - y15-34 (VA29) (+) | Always | 50 kΩ or more |

| 30 | y15-34 (VA29) (-) - y15-11 (VA30) (+) | Always | 50 kΩ or more |

| 31 | y15-11 (VA30) (-) - y15-23 (VA31) (+) | Always | 50 kΩ or more |

| 32 | y15-23 (VA31) (-) - y15-35 (VA32) (+) | Always | 50 kΩ or more |

| 33 | y15-35 (VA32) (-) - y15-12 (VA33) (+) | Always | 50 kΩ or more |

| 34 | y15-12 (VA33) (-) - y15-24 (VA34) (+) | Always | 50 kΩ or more |

| 35 | y15-24 (VA34) (-) - y15-36 (VA35) (+) | Always | 50 kΩ or more |

NOTICE:

- Make sure to check the polarity of each terminal (positive (+) or negative (-)) before connecting a tester.

- Read the resistance after the value has stabilized.

- In order to avoid damaging the terminals of the battery ECU assembly, make sure to use tester probes with a diameter of approximately 0.5 mm (0.0197 in.) when measuring the resistance of the battery ECU assembly.

(c) Install the battery ECU assembly.

| Result | Proceed to |

|---|---|

| The voltage between the terminals is 50 kΩ or more. | A |

| Other than above | B |

| A | .gif) | REPLACE NO. 1 HV SUPPLY STACK SUB-ASSEMBLY |

|

| 7. | REPLACE NO. 1 HV SUPPLY STACK SUB-ASSEMBLY |

Click here .gif)

.gif)

| NEXT | .gif) | REPLACE BATTERY ECU ASSEMBLY |

| 8. | CHECK CONNECTOR CONNECTION CONDITION (BATTERY ECU ASSEMBLY CONNECTOR) |

CAUTION:

Be sure to wear insulated gloves and protective goggles.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the No. 1 HV battery hose.

Click here .gif)

.gif)

| (c) Check the connector connections and contact pressure of the relevant terminals for the battery ECU assembly. Click here OK: The connector is connected securely and there are no contact problems.

|

| |||||||||||||

(d) Install the No. 1 HV battery hose.

| B | .gif) | CONNECT SECURELY |

| C | .gif) | REPLACE NO. 2 HV SUPPLY STACK SUB-ASSEMBLY |

|

| 9. | CHECK FREEZE FRAME DATA (HV BATTERY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Powertrain / HV battery / Trouble Codes.

(d) Read the value of freeze frame data items "Hybrid/EV Battery Cell 36 Voltage" through "Hybrid/EV Battery Cell 70 Voltage" for DTC P33ED16 and make a note if the value of any is 1.2 V or less.

Powertrain > HV Battery > Trouble Codes(e) Turn the power switch off.

|

| 10. | CHECK NO. 2 HV SUPPLY STACK SUB-ASSEMBLY (HV BATTERY CELL VOLTAGE) |

CAUTION:

- Be sure to wear insulated gloves and protective goggles.

- Disconnect only the connector corresponding to the HV battery cell to be checked. Do not disconnect the other connectors.

NOTICE:

Make sure to use tester probes with a diameter of approximately 0.5 mm (0.0197 in.) when measuring the voltage of each HV battery cell.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the No. 1 HV battery hose.

Click here .gif)

.gif)

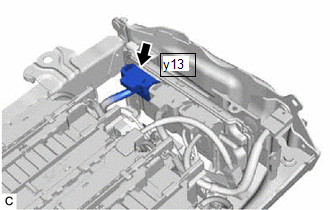

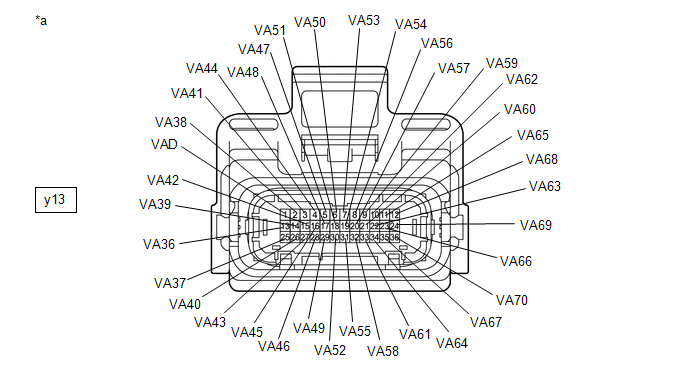

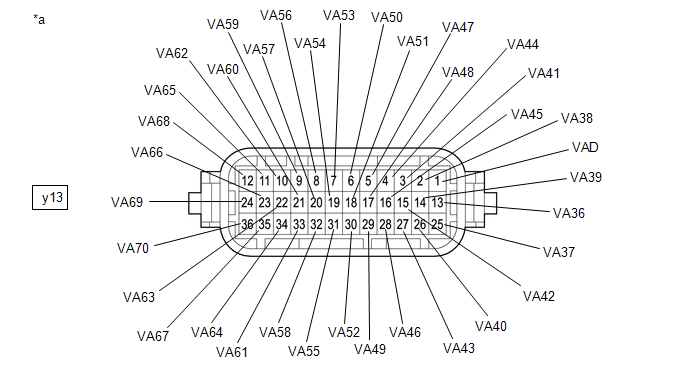

| (c) Disconnect the y13 battery ECU assembly connector. |

|

(d) Measure the voltage according to the value(s) in the table below.

HINT:

Measure the voltage of the HV battery cells whose value in the freeze frame data was 1.2 V or less only.

| *a | Front view of wire harness connector (to Battery ECU Assembly) | - | - |

| HV Battery Cell | Tester Connection | Condition |

|---|---|---|

| 36 | y13-1 (VAD) - y13-13 (VA36) | Always |

| 37 | y13-13 (VA36) - y13-25 (VA37) | Always |

| 38 | y13-25 (VA37) - y13-2 (VA38) | Always |

| 39 | y13-2 (VA38) - y13-14 (VA39) | Always |

| 40 | y13-14 (VA39) - y13-26 (VA40) | Always |

| 41 | y13-26 (VA40) - y13-3 (VA41) | Always |

| 42 | y13-3 (VA41) - y13-15 (VA42) | Always |

| 43 | y13-15 (VA42) - y13-27 (VA43) | Always |

| 44 | y13-27 (VA43) - y13-4 (VA44) | Always |

| 45 | y13-4 (VA44) - y13-16 (VA45) | Always |

| 46 | y13-16 (VA45) - y13-28 (VA46) | Always |

| 47 | y13-28 (VA46) - y13-5 (VA47) | Always |

| 48 | y13-5 (VA47) - y13-17 (VA48) | Always |

| 49 | y13-17 (VA48) - y13-29 (VA49) | Always |

| 50 | y13-29 (VA49) - y13-6 (VA50) | Always |

| 51 | y13-6 (VA50) - y13-18 (VA51) | Always |

| 52 | y13-18 (VA51) - y13-30 (VA52) | Always |

| 53 | y13-30 (VA52) - y13-7 (VA53) | Always |

| 54 | y13-7 (VA53) - y13-19 (VA54) | Always |

| 55 | y13-19 (VA54) - y13-31 (VA55) | Always |

| 56 | y13-31 (VA55) - y13-8 (VA56) | Always |

| 57 | y13-8 (VA56) - y13-20 (VA57) | Always |

| 58 | y13-20 (VA57) - y13-32 (VA58) | Always |

| 59 | y13-32 (VA58) - y13-9 (VA59) | Always |

| 60 | y13-9 (VA59) - y13-21 (VA60) | Always |

| 61 | y13-21 (VA60) - y13-33 (VA61) | Always |

| 62 | y13-33 (VA61) - y13-10 (VA62) | Always |

| 63 | y13-10 (VA62) - y13-22 (VA63) | Always |

| 64 | y13-22 (VA63) - y13-34 (VA64) | Always |

| 65 | y13-34 (VA64) - y13-11 (VA65) | Always |

| 66 | y13-11 (VA65) - y13-23 (VA66) | Always |

| 67 | y13-23 (VA66) - y13-35 (VA67) | Always |

| 68 | y13-35 (VA67) - y13-12 (VA68) | Always |

| 69 | y13-12 (VA68) - y13-24 (VA69) | Always |

| 70 | y13-24 (VA69) - y13-36 (VA70) | Always |

CAUTION:

Make sure not to cross the electrodes of an electrical tester measurement terminals.

NOTICE:

Make sure to check the polarity of each terminal (positive (+) or negative (-)) before connecting a tester.

| Result | Proceed to |

|---|---|

| The voltage between the terminals is 1.2 V or less. | A |

| Other than above | B |

(e) Reconnect the y13 battery ECU assembly connector.

(f) Install the No. 1 HV battery hose.

| B | .gif) | REPLACE BATTERY ECU ASSEMBLY |

|

| 11. | CHECK BATTERY ECU ASSEMBLY (VAD - VA70) |

NOTICE:

Make sure to use tester probes with a diameter of approximately 0.5 mm (0.0197 in.) when measuring the resistance.

(a) Remove the battery ECU assembly.

Click here .gif)

.gif)

(b) Measure the resistance according to the value(s) in the table below.

HINT:

Only inspect the terminals of the battery ECU assembly which correspond to the HV battery cells which measured 1.2 V or less in the previous step.

| *a | Component without harness connected (Battery ECU Assembly) | - | - |

Standard Resistance:

| HV Battery Cell | Tester Connection (Tester Probe Polarity) | Condition | Specified Condition |

|---|---|---|---|

| 36 | y13-1 (VAD) (-) - y13-13 (VA36) (+) | Always | 50 kΩ or more |

| 37 | y13-13 (VA36) (-) - y13-25 (VA37) (+) | Always | 50 kΩ or more |

| 38 | y13-25 (VA37) (-) - y13-2 (VA38) (+) | Always | 50 kΩ or more |

| 39 | y13-2 (VA38) (-) - y13-14 (VA39) (+) | Always | 50 kΩ or more |

| 40 | y13-14 (VA39) (-) - y13-26 (VA40) (+) | Always | 50 kΩ or more |

| 41 | y13-26 (VA40) (-) - y13-3 (VA41) (+) | Always | 50 kΩ or more |

| 42 | y13-3 (VA41) (-) - y13-15 (VA42) (+) | Always | 50 kΩ or more |

| 43 | y13-15 (VA42) (-) - y13-27 (VA43) (+) | Always | 50 kΩ or more |

| 44 | y13-27 (VA43) (-) - y13-4 (VA44) (+) | Always | 50 kΩ or more |

| 45 | y13-4 (VA44) (-) - y13-16 (VA45) (+) | Always | 50 kΩ or more |

| 46 | y13-16 (VA45) (-) - y13-28 (VA46) (+) | Always | 50 kΩ or more |

| 47 | y13-28 (VA46) (-) - y13-5 (VA47) (+) | Always | 50 kΩ or more |

| 48 | y13-5 (VA47) (-) - y13-17 (VA48) (+) | Always | 50 kΩ or more |

| 49 | y13-17 (VA48) (-) - y13-29 (VA49) (+) | Always | 50 kΩ or more |

| 50 | y13-29 (VA49) (-) - y13-6 (VA50) (+) | Always | 50 kΩ or more |

| 51 | y13-6 (VA50) (-) - y13-18 (VA51) (+) | Always | 50 kΩ or more |

| 52 | y13-18 (VA51) (-) - y13-30 (VA52) (+) | Always | 50 kΩ or more |

| 53 | y13-30 (VA52) (-) - y13-7 (VA53) (+) | Always | 50 kΩ or more |

| 54 | y13-7 (VA53) (-) - y13-19 (VA54) (+) | Always | 50 kΩ or more |

| 55 | y13-19 (VA54) (-) - y13-31 (VA55) (+) | Always | 50 kΩ or more |

| 56 | y13-31 (VA55) (-) - y13-8 (VA56) (+) | Always | 50 kΩ or more |

| 57 | y13-8 (VA56) (-) - y13-20 (VA57) (+) | Always | 50 kΩ or more |

| 58 | y13-20 (VA57) (-) - y13-32 (VA58) (+) | Always | 50 kΩ or more |

| 59 | y13-32 (VA58) (-) - y13-9 (VA59) (+) | Always | 50 kΩ or more |

| 60 | y13-9 (VA59) (-) - y13-21 (VA60) (+) | Always | 50 kΩ or more |

| 61 | y13-21 (VA60) (-) - y13-33 (VA61) (+) | Always | 50 kΩ or more |

| 62 | y13-33 (VA61) (-) - y13-10 (VA62) (+) | Always | 50 kΩ or more |

| 63 | y13-10 (VA62) (-) - y13-22 (VA63) (+) | Always | 50 kΩ or more |

| 64 | y13-22 (VA63) (-) - y13-34 (VA64) (+) | Always | 50 kΩ or more |

| 65 | y13-34 (VA64) (-) - y13-11 (VA65) (+) | Always | 50 kΩ or more |

| 66 | y13-11 (VA65) (-) - y13-23 (VA66) (+) | Always | 50 kΩ or more |

| 67 | y13-23 (VA66) (-) - y13-35 (VA67) (+) | Always | 50 kΩ or more |

| 68 | y13-35 (VA67) (-) - y13-12 (VA68) (+) | Always | 50 kΩ or more |

| 69 | y13-12 (VA68) (-) - y13-24 (VA69) (+) | Always | 50 kΩ or more |

| 70 | y13-24 (VA69) (-) - y13-36 (VA70) (+) | Always | 50 kΩ or more |

NOTICE:

- Make sure to check the polarity of each terminal (positive (+) or negative (-)) before connecting a tester.

- Read the resistance after the value has stabilized.

- In order to avoid damaging the terminals of the battery ECU assembly, make sure to use tester probes with a diameter of approximately 0.5 mm (0.0197 in.) when measuring the resistance of the battery ECU assembly.

(c) Install the battery ECU assembly.

| Result | Proceed to |

|---|---|

| The voltage between the terminals is 50 kΩ or more. | A |

| Other than above | B |

| A | .gif) | REPLACE NO. 2 HV SUPPLY STACK SUB-ASSEMBLY |

|

| 12. | REPLACE NO. 2 HV SUPPLY STACK SUB-ASSEMBLY |

Click here .gif)

.gif)

| NEXT | .gif) | REPLACE BATTERY ECU ASSEMBLY |

.gif)